Welding is one of the most essential processes in manufacturing, yet the expectations around speed, quality, and consistency have changed dramatically in recent years. Whether you’re building automotive components, aerospace assemblies, consumer products, or custom metalwork, production demands continue to grow while the availability of skilled welders declines. These challenges are prompting many factories to adopt newer technologies specifically, the industrial laser welder, a solution known for delivering fast, precise, and highly repeatable welds.

But how exactly does an industrial laser welder differ from traditional welding methods like MIG, TIG, and stick welding? And more importantly, how do you know which method aligns with your production requirements? This guide breaks down the key differences so you can make an informed, practical decision for your manufacturing workflow.

Understanding the Core Pain Points in Today’s Welding Workflows

Before comparing the two technologies, it’s important to understand the challenges manufacturers face:

- Variability in weld quality, especially when dependent on manual skill

- Heat distortion, leading to rework and material waste

- Slow cycle times associated with traditional welding processes

- Difficulty meeting tight tolerances in high-precision industries

An industrial laser welder is often considered an upgrade because it directly addresses many of these issues.

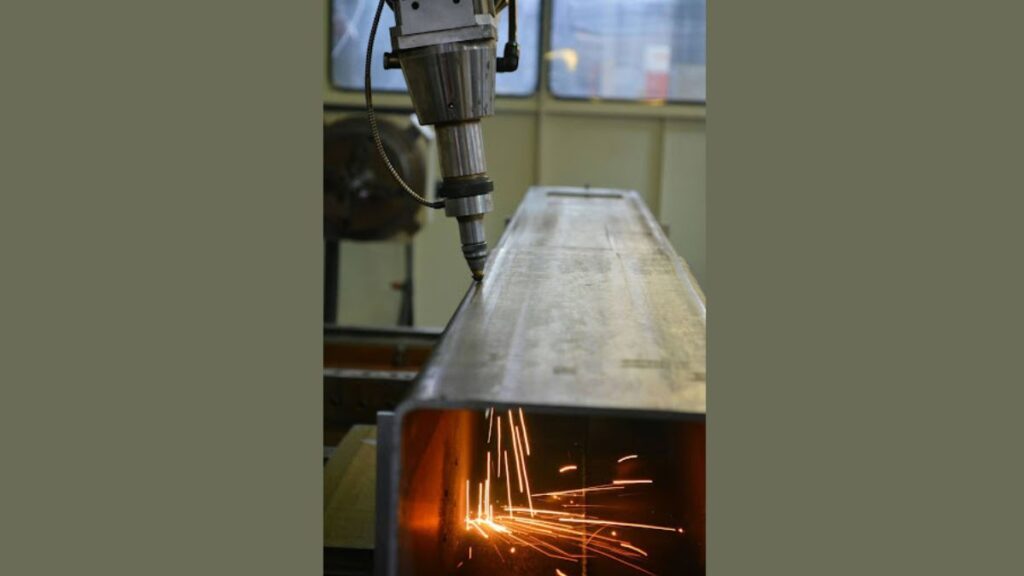

How Industrial Laser Welding Works

Laser welding uses a concentrated, high-energy beam of light to melt and fuse metal. Because the beam can be incredibly narrow and tightly controlled, the process provides exceptional precision with minimal heat input.

Key characteristics of laser welding:

- A small, focused heat-affected zone (HAZ)

- Extremely fast welding speeds

- Clean, narrow weld seams

- Minimal spatter and distortion

- Excellent repeatability for automation

These qualities make laser welding ideal for industries where accuracy and consistency are critical.

How Traditional Welding Works

Traditional welding methods MIG, TIG, and stick use an electrical arc to generate heat and melt metal. While these methods remain valuable and widely used, they involve more manual control, more heat, and more variation.

Common characteristics of traditional welding:

- Higher heat input and wider HAZ

- More spatter, smoke, and cleanup

- Lower travel speeds

- Greater dependency on operator skill

- More distortion on thin or sensitive material.

Traditional welding excels in certain applications, especially those involving thick materials or structural components.

Key Differences Between Laser Welding and Traditional Welding

Here’s a clear breakdown of how the processes differ:

Heat Input

- Industrial Laser Welder: Low heat, minimal deformation

- Traditional Welding: High heat, higher risk of part warping

Weld Quality

- Laser: Consistent, repeatable, clean

- Traditional: Variable based on skill and settings

Speed

- Laser: Extremely fast, especially on thin materials

- Traditional: Moderate to slow depending on weld type

Operator Skill

- Laser: Less dependent on manual skill, especially when automated

- Traditional: High skill levels required for quality welds

Material Compatibility

Both processes work on steel, stainless, aluminum, titanium, and other alloys, but laser welding is especially beneficial for thin materials and precision assemblies.

Comparison Table: Industrial Laser Welder vs Traditional Welding

| Feature | Industrial Laser Welder | Traditional Welding |

| Heat Distortion | Very Low | Moderate to High |

| Weld Speed | Fast | Slow to Medium |

| Operator Skill Required | Low–Moderate | High |

| Cosmetic Quality | Excellent | Good–Moderate |

| Automation Compatibility | Excellent | Moderate |

| Cleaning/Finishing Needs | Minimal | Often Required |

| Best For | Thin metals, precision work, high-volume production | Structural welding, thick materials |

When an Industrial Laser Welder Makes the Most Sense

Laser welding is not a universal replacement for traditional welding, but it offers major advantages in certain situations.

Ideal scenarios for an industrial laser welder:

- High-volume production where speed matters

- Thin materials prone to heat distortion

- Parts requiring tight tolerances

- Cosmetic welds that must be visually clean

- Automated or robotic workflows

- Industries with strict quality standards, such as medical and aerospace

If your production requires fast cycles, consistent results, or precision welding, laser technology is likely the better investment.

When Traditional Welding May Still Be the Better Fit

There are still plenty of use cases where MIG, TIG, or stick welding remains practical.

Best use cases for traditional welding:

- Thick structural steel

- Outdoor or field welding

- Projects requiring high penetration

- Situations where equipment must be highly portabl

- Repairs or low-volume custom fabrication

Because arc welding is versatile and affordable, it remains essential in many industries.

Automation and Workflow Differences

One of the biggest distinctions between the two technologies is how easily they integrate with automation.

Laser Welding and Automation

- Works seamlessly with robots and cobots

- Requires consistent part placement

- Ideal for repetitive, high-volume welds

- Increases output with minimal supervision

Traditional Welding and Automation

- Automation is possible but more complex

- Heat and spatter can require more shielding

- Requires more specialized programming

For factories embracing Industry 4.0, the industrial laser welder is often the preferred option.

Cost, ROI, and Long-Term Value

While an industrial laser welder may have a higher initial cost, it often delivers long-term savings through:

- Faster production cycles

- Reduced scrap and rework

- Lower consumable usage

- Minimal post-processing

- Increased automation compatibility

ROI varies, but many manufacturers see payback within 12–36 months depending on volume.

If you’re evaluating which welding approach fits your workflow, comparing equipment options can help you understand how different tools perform under real production conditions. Many manufacturers reference systems from brands like Denaliweld when exploring laser welding technology for precision-driven applications.

Conclusion

Both traditional welding and laser welding play important roles in modern manufacturing, but they serve different needs. Traditional welding remains ideal for thick materials, field work, and structural applications where deep penetration and flexibility matter. In contrast, the industrial laser welder excels in fast-paced production environments that require precision, repeatability, and minimal heat distortion.

By understanding the strengths and limitations of each process, you can better align your welding technology with your production goals. Whether you’re aiming to improve throughput, reduce rework, or achieve cleaner cosmetic welds, selecting the right welding method is a powerful step toward a more efficient and future-ready manufacturing workflow.