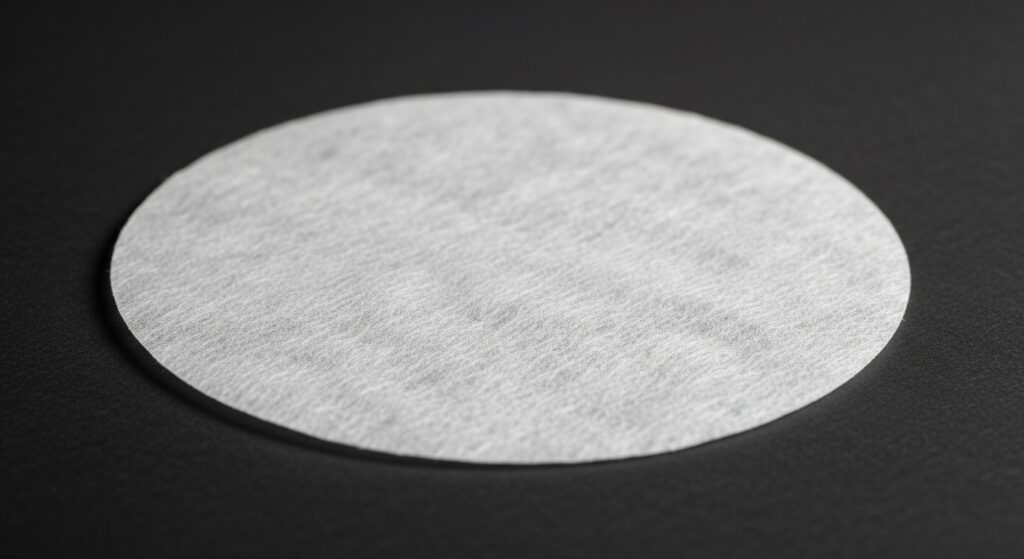

In scientific and laboratory settings, small details often determine the success or accuracy of an experiment. One such crucial detail lies in a simple yet indispensable tool—the filter paper. While it may appear unassuming at first glance, the appearance of filter paper reveals a great deal about its quality, structure, and intended use. Understanding these visual and textural features not only helps in proper selection but also enhances the precision and efficiency of laboratory work.

This article explores the composition, structure, and types of filter paper, how its appearance varies depending on use, and why recognizing these subtle distinctions is essential for scientists, students, and professionals alike.

What Is Filter Paper?

Filter paper is a specialized type of paper primarily used for separating fine substances or impurities from liquids and gases. It acts as a semi-permeable barrier, allowing certain particles to pass through while retaining others. Typically made from cellulose fibers derived from wood or cotton, filter paper is known for its uniform texture, high absorbency, and mechanical strength when wet.

The appearance of filter paper is not merely aesthetic—it reflects the quality and performance of the paper in filtration processes. Characteristics such as texture, thickness, color, and surface uniformity often provide important clues about the type of filtration it is designed for.

The Physical Appearance of Filter Paper

The most common visual and tactile features of filter paper include:

-

Color: Filter paper is usually white or off-white, symbolizing purity and the absence of contaminants. Some types may have a slightly yellowish hue if untreated or designed for specific chemical applications.

-

Texture: The surface of filter paper can range from smooth and uniform to rough and fibrous, depending on its pore size and manufacturing method.

-

Thickness: Thicker papers tend to have slower filtration rates but higher retention efficiency, while thinner papers allow faster flow with less particle capture.

-

Porosity: The presence of tiny pores is one of the defining characteristics. These pores determine the filtration capacity and are often visible under magnification.

-

Edge and Shape: Most laboratory filter papers are circular and come with sharply cut edges, though they may also be folded or pleated for different applications.

In essence, the appearance of filter paper gives direct insight into its composition and expected performance in scientific applications.

Types of Filter Paper and Their Distinct Appearances

There are several kinds of filter papers, each with a unique look and texture suited for different scientific and industrial purposes.

-

Qualitative Filter Paper:

Used primarily for educational and routine laboratory experiments, this type typically appears smooth, white, and thin. It provides quick filtration but may not capture extremely fine particles. -

Quantitative (Ashless) Filter Paper:

This paper has a cleaner, almost glossy white appearance because it is acid-treated to remove impurities. It is commonly used in gravimetric and quantitative chemical analyses where precision is key. -

Glass Microfiber Filter Paper:

Unlike cellulose-based papers, this type has a slightly translucent, fibrous appearance. It is often used for air or gas filtration and offers superior retention of fine particles. -

Membrane Filter Paper:

This kind features a smooth, uniform surface that resembles thin plastic. Its microscopic pore structure allows for precise filtration, commonly used in microbiology to trap microorganisms. -

Creped Filter Paper:

Recognized by its wrinkled or crinkled texture, creped filter paper offers a larger surface area for filtration, improving flow rates in certain applications.

By observing these distinctions in the appearance of filter paper, laboratory professionals can easily identify which type best suits their experiment or industrial process.

Factors Influencing the Appearance of Filter Paper

Several factors affect how filter paper looks and performs:

-

Manufacturing Process: The method of fiber bonding, pressing, and drying influences surface uniformity and thickness.

-

Chemical Treatment: Some filter papers undergo acid washing or surface coating to remove trace elements, making them appear brighter and smoother.

-

Fiber Source: Wood-based cellulose results in slightly rougher paper, whereas cotton-based fibers produce softer, more uniform surfaces.

-

Storage and Age: Prolonged exposure to moisture, light, or dust can alter the paper’s color—causing yellowing or uneven stains.

Therefore, when assessing the appearance of filter paper, it’s essential to consider whether it is new, treated, or affected by environmental conditions.

The Role of Appearance in Filter Paper Performance

Beyond its visual attributes, the appearance of filter paper often correlates with specific performance characteristics:

-

Smooth surfaces typically indicate even pore distribution, resulting in more consistent filtration.

-

Uniform color suggests purity and minimal contamination, which is essential for analytical work.

-

Visible fibers or uneven texture may indicate a coarser filtration grade suitable for larger particles.

For example, a thick, fibrous-looking paper might be ideal for filtering sediments from liquids, whereas a thin, smooth, white paper would suit analytical chemistry where precision is vital. Recognizing these subtle signs helps ensure that the right paper is chosen for each task.

Applications Across Different Fields

The importance of understanding the appearance of filter paper extends beyond laboratories. It plays a key role across several industries:

-

Environmental Science: For monitoring air and water quality, where specific grades of filter paper capture pollutants.

-

Food and Beverage Industry: Used to clarify liquids such as oils, syrups, and beverages, requiring papers with smooth, high-purity surfaces.

-

Medical and Pharmaceutical Fields: In diagnostic tests and sample preparation, where the appearance can indicate sterility and consistency.

-

Art and Design: Certain artists even use high-grade filter paper for its absorbency and smoothness in mixed media work.

Each of these applications benefits from recognizing and selecting the right paper based on its visible and structural characteristics.

Challenges in Evaluating Filter Paper Appearance

While appearance provides valuable information, it cannot always guarantee quality. For instance, two filter papers may look identical but perform differently due to variations in pore size, fiber alignment, or chemical composition. Therefore, while visual inspection is a good starting point, technical data sheets and manufacturer specifications should also be reviewed for critical applications.

Looking Ahead: Innovation in Filter Paper Design

Modern technology continues to refine how filter papers are made and used. Advances in nanofiber engineering, biodegradable materials, and digital quality control are leading to new papers that look and perform better than ever. Future versions may feature color indicators or texture variations that visually signal when filtration is complete.

As science advances, understanding the appearance of filter paper will remain a vital aspect of laboratory efficiency, ensuring accuracy and sustainability in every process.

Conclusion

The appearance of filter paper is more than just a visual feature—it’s a reflection of quality, structure, and purpose. By learning to identify subtle differences in color, texture, and porosity, scientists and professionals can select the right paper for each application, ensuring precision and reliability. As technology evolves, this simple yet powerful tool will continue to play a central role in research, industry, and innovation.